|

1. Brief introduction of product:

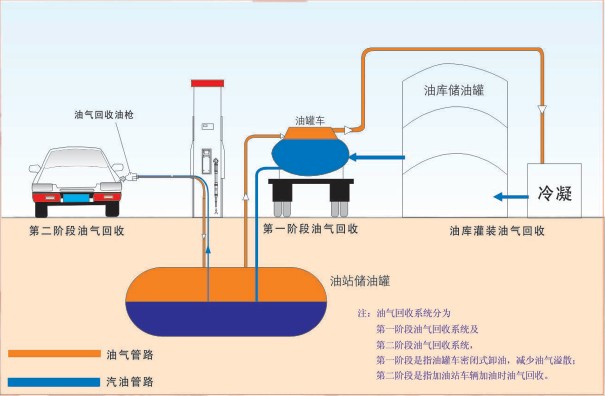

Recovery rate of oil vapor recovery system can reach to 90-99%. There are four basic methods for oil and gas recovery system the most commonly used: adsorption, absorption, condensation and membrane separation method. Active carbon absorption vacuum recycling device is simple and practical, especially suitable for the gasoline vapor recovery oil depot.The device has the advantages of simple structure, high efficiency, especially for small and medium sized oil depot; The condensation and absorption device is the best recovery device on the market. It is especially suitable for large oil depot with a peak flow; Oil tank can be a plurality of tank the top outlet pipe connected to a common oil and gas recovery device, the liquid pump absorption after the return tank.

Since 2000 the company has long-term commitment to new product oil and gas recovery device research, development, production and improvement, has participated in the 2008 Beijing Olympic Games, oil depot of Shanghai World Expo 2010, Guangzhou 2011 Asian Games and other major city of the gas station and oil and gas recovery project, performance throughout the country, has made great achievements, accumulated rich scientific and technological achievements and practical experience, the oil and gas recovery unit was awarded the national electrical explosion-proof inspection center of the production license, company hired perennial domestic environmental protection industry, chemical engineering industry influential experts and professors as technical advisor to the company, and with the CSIC Wuchang shipyard, CSIC Institute, Wuhan University, Shanghai 711 Hubei University, Wuhan Institute of Technology, the group (the original four) research design department 10 tertiary institutions, established long-term cooperation relationship of technical cooperation, and has achieved the leading domestic level with the oil and gas recovery technology.

2. Main methods:

1) Adsorption method:

The hydrocarbon containing gas storage and transportation enter into the activated carbon bed, in which oil and gas adsorption on the surface of activated carbon. The purified gas is directly discharged to the atmosphere, the adsorption of oil and gas by vacuum pump desorption into the separator, the separator, oil and gas into the absorption tower, the tower is absorbed by the oil spray. At normal temperature and pressure, the oil and gas adsorption, desorption is achieved in the vacuum state, respectively, adsorption and desorption, switching operation, ensure the continuous operation of the device. Oil and gas absorption rate can reach 99%, exhaust gas hydrocarbon content low, meet the requirements of emission standards for strict oil gas, suitable for petrochemical enterprises, small scale and in oil depot oil storage and shipment.

2) Condensation method:

Oil and gas enter into the absorption tower, cold logistics in contact with the top spray. For the liquid pressure is low and flow is strong, phase equilibrium partial pressure ratio of oil and gas pressure, most of the oil and gas cannot continue in a gas phase, it was cold liquid absorption. Purified gas directly into the atmosphere after absorption. Cold liquid oil gas into the desorption tower, the heating will be released from oil and gas, oil and gas into the absorption tower, absorbed by the spray of gasoline, and cold solvent absorption after the cooling cycle. Oil and gas recovery large shipping facilities suitable for peak flow absorption rate is relatively high, exhaust gas hydrocarbon content is generally 20g/m3, can meet the general requirements of the oil and gas emission.

3) Absorption method:

Oil and gas enter into the oil and gas absorption tower through the solvent spray, purified gas is directly discharged into the atmosphere after absorption, petroleum solvents into the vacuum desorption tower, the adsorbed hydrocarbon after vacuum pump desorption into the separator, the separator, oil and gas into the absorption tower, absorbed by the spray of gasoline, desorption after the solvent through the pump into the oil and gas absorption tower circulation. Large shipping facilities suitable for peak flow (pier) oil and gas recovery, oil and gas absorption rate can reach 90%.

3. Installation instruction:

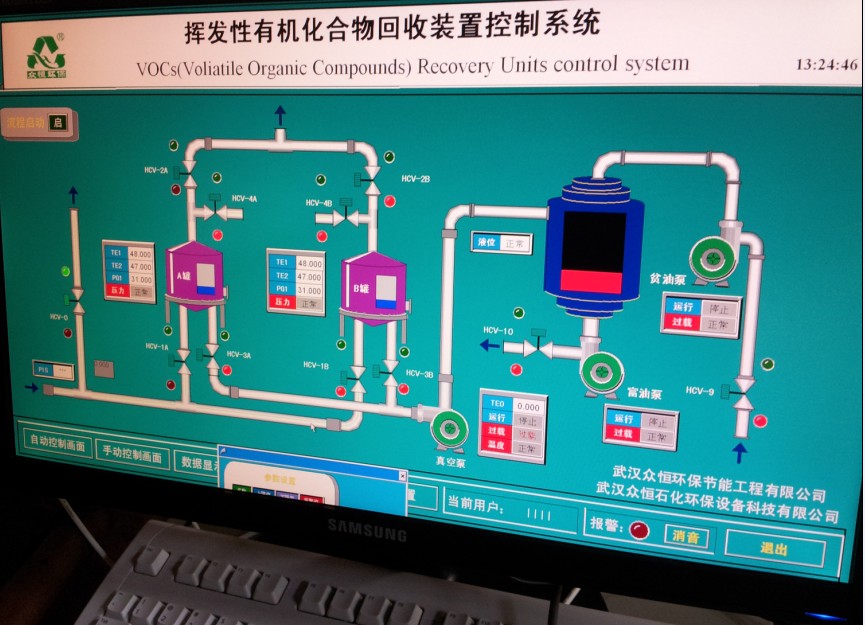

4. Recovery units control system:

|